I ❤ Wood

I ❤ Wood

- Started

- Last post

- 1,050 Responses

- HijoDMaite1

- $300?BabySnakes

- Damn. That looks sturdy.pango

- flatscreens are hard to make from scratch. the remote control and cablebox will cost you too.sarahfailin

- Depends how you source the wood and if you build it yourself.BK

- If you jack a bunch of pallets, plane them down and get your carpenter on, could be free.BK

- i might try that BK, @baby snakes you think $300 for the cost of the wood?HijoDMaite

- just go buy one from tj maxximbecile

- ********0

- If you can be bothered, scoot back a few pages and see an image I posted, which does exactly this, but usingh a laser. Coems out SOOO beautifully.detritus

- i couldn't find it.********

- detritus0

- There's 'a thing' - a very cool 'thing', a very expensive 'thing' that can be rented for about £5k a week. I want one to spend a few days just making <these.detritus

- otherwise <that takes ages to make, layer by layer slowly ablating top surfaces. Can't put in too much power with every pass, otherwise it all just burns to shtdetritus

- http://lasermake.co.…detritus

- its a nice effect.********

- you're looking to rent a laser?********

- at those prices, you could just buy your own.********

- No, I have a laser - what I'm after is a specific type of device, very rare and costing upwards of three quarters of a million to buy.detritus

- I've been trying to work out how to make one, but I'm not smart enough.detritus

- that's a lot of money to make a wood grained tile. I'm guessing you're looking to make something much bigger.********

- 1000s of wood grained tiles :)detritus

- bet you could do it better with a cnc router to avoid the burning.********

- No, a CNC has no way of understanding where the lay of the wood's inherent contours are.detritus

- Sand-blasting and lasering are discriminate - they only affect the softer or more burnable portions of the wood, thereby describing its character.detritus

- I have wondered at creating a bitmap contour and CNCing or lasering a piece of wood, but the problem is that a surface scan doesn't represent what is underneathdetritus

- so even a mill, or two, or three under surface, and already your contour map doesn't match the actual grain and form of the wood through its bulk.detritus

- so how would you get rid of the burning?********

- the discoloration and smell is horrible.********

- you don't go at it full whack :)

the laser can be set fine enough to just ablate the top percentage of a millimetre, so you just repeat downwards..detritus - ..sort of like the inverse of a 3D printer.

And yes, the smell can be awful - walnut is sickening :\detritus - that hardwood must take longer. I'll rarely work with wood in my laser due to the smells.********

- i wish i could, but maybe someday.********

- Eh? What sort of laser do you run.. and what for? That your business?detritus

- It's used primarily for business. Prototype research, manufacture low run in-house product design work. It's not used as a laser service for other businesses.********

- It's a 45w laser. What your laser used for?********

- Epilog? I run a laser cutting servicedetritus

- Oh, those are nice. Fslaser is the brand I choose.********

- ********0

- ********0

- microkorg-1

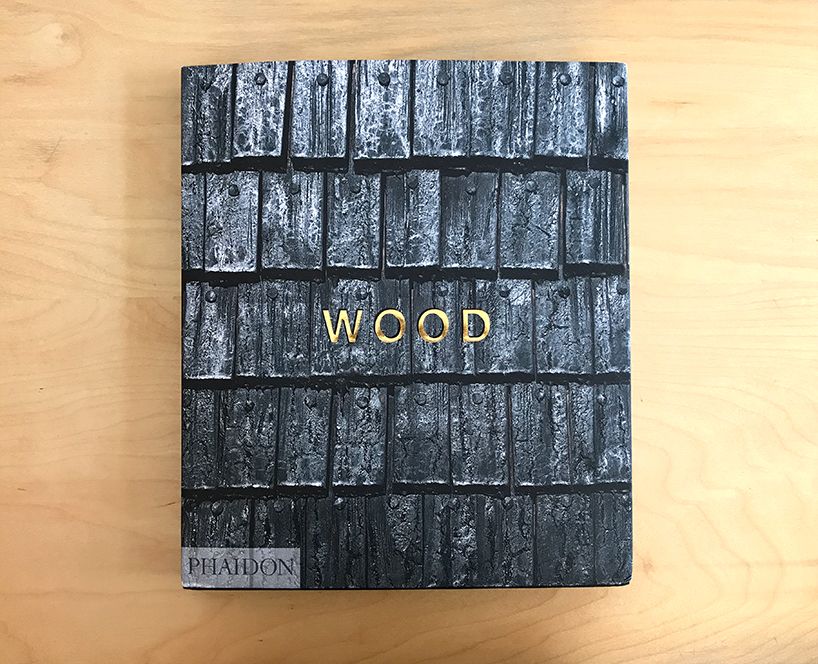

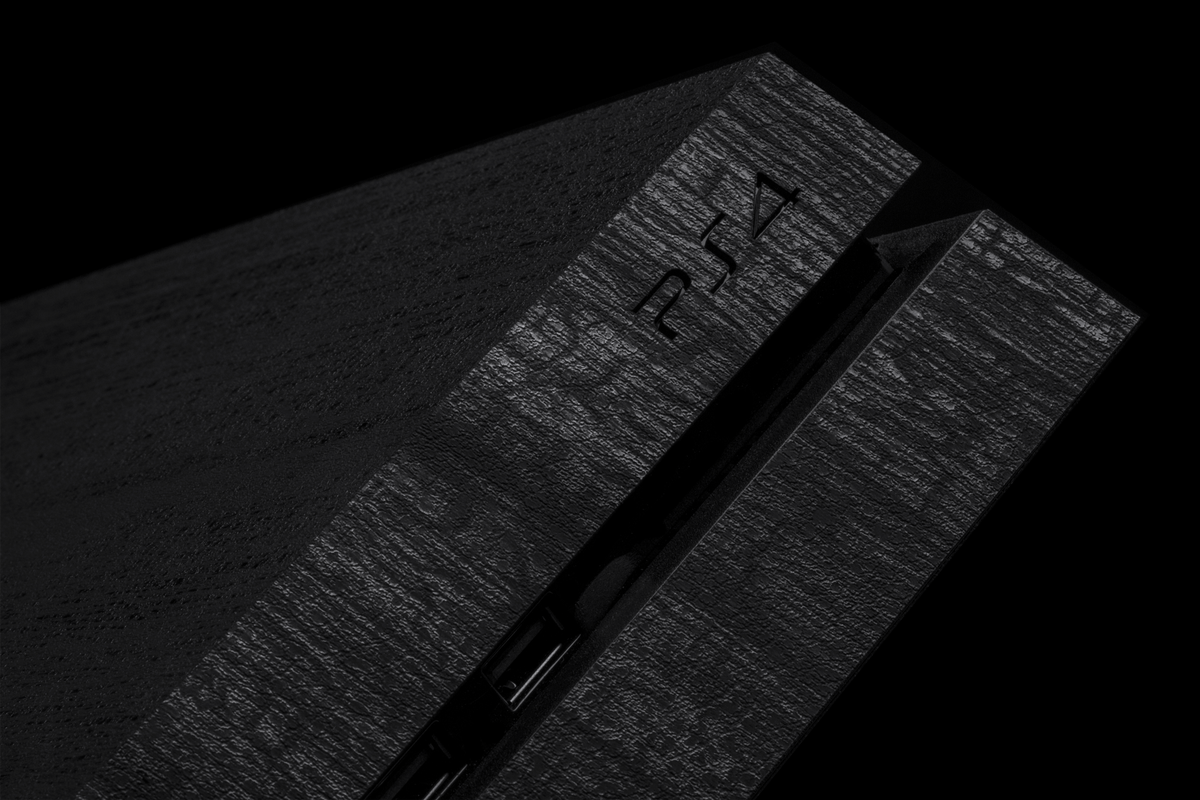

Looking for skins for my laptop and I found this new offering from https://dbrand.com

It's called "Black Dragon"

Seemingly it's a "grippy" surface not like some of their (and others) other skins.

Thought I'd post it here as it looks like charred wood.

Pretty cool looking.- It was the "WOOD" post previous that reminded me of this skin I saw the other day.microkorg

- i work at slickwraps.com

hit me up if we can helpimbecile - Boo, it's just vinyl?detritus

- That is a 3M architectural vinyl. At Slickwraps we have a natural series with bamboo, mahogany, etc.. including a black ash.imbecile